Why Choose Advance CNC Machining Services?

At Advance CNC, serving customers is a privilege we don’t take for granted.

Our team works hard to earn your trust by delivering quality and value in each project. If you’re tired of unreliable manufacturing teams, you can rest easy knowing Advance CNC will produce high quality parts at a great value — every single time.

- Quality Guaranteed

- Exceptional Value

- Reliable Service

- Stocking Program

At Advance CNC Machining, it’s our goal to provide you with high-quality parts you can depend on.

Our People

We only hire great people who commit to doing quality work and taking care of customers.

Technology

Robotic loaders and pallet systems allow for “lights out” production.

High Standards

Track Record

Equipment

Advance CNC uses high speed, highly precise Makino 4-axis and 5-axis machining centers almost exclusively.

Measurement

We invest in CMMs, optical scanning and optical imaging equipment that most shops don’t have.

Training

Automation

We invest in precise automation to ensure repeatable quality 24 hours a day.

We believe in providing our customers with more than just a competitive price. And we believe in providing exceptional value in CNC Machining. Here are eight ways we back it up and offer more:

Speed

We have some of the fastest machining centers on the market. This means lower prices for you.

Efficiency

Expect shorter lead times because we run 24 hours a day.

Extensive

We can be a one-stop source for machining and gears, secondary operations and assembly if you wish.

Certified

We can supply material certifications and certificates of conformance with any order at no charge.

Low Inventory Cost

We’ll spread out shipments so you can keep inventories low.

Shipping

We’ll coordinate the freight; you don’t have to.

Consignment

For customers that qualify, we’ll sell parts on consignment, virtually eliminating your inventory.

Value

Because of our size, we get competitive material prices that we pass along.

Advance CNC Machining wants to be a manufacturing partner you can trust with all of your custom machining needs. Why you can count on us for reliable service:

- 99.3% of our shipments are made on-time.

- Expect our quotes within 48 hours.

- We’ll come to you whenever you need us.

- Dedicated account managers whose only job is to take care of you.

- We do what we say we’ll do. No surprises.

Need to reduce expenses? Our CNC Machining Stocking Program will start saving you money today! Our convenient stocking program allows us to stock our customers’ parts on our shelves to be shipped on their requested dates. Most of our customers require 50 – 50,000 of any single part number in a year. America’s top manufacturing companies actively rely on Advance CNC Machining for their machined parts. For some, freight expense was a factor, so we offered them free freight. Now they can compare apples to apples when deciding on a machining partner.

With Advance CNC Machining's Stocking Program, you can:

- Receive maximum discount pricing and enjoy fixed costs for parts that you’ve enrolled in our Stocking Program

- Reduce your inventory costs

- Improve your cash flow

- Dedicated account managers whose only job is to take care of you.

- We do what we say we’ll do. No surprises.

Relax because delivery of your parts is no longer tied to production & machining lead times

How does it work? Simple.

- You issue a purchase order for the entire quantity of parts you are ordering, taking advantage of our large-quantity price break.

- You pay only as parts are released.

- You save the costs associated with carrying and managing the inventory.

- You have the advantage of knowing that your parts will be ready and waiting when you need to have them shipped.

We will customize a Stocking Program to meet your needs. Contact us for a free quote to start saving time and money today.

in business

parts in inventory

team members

What we Do

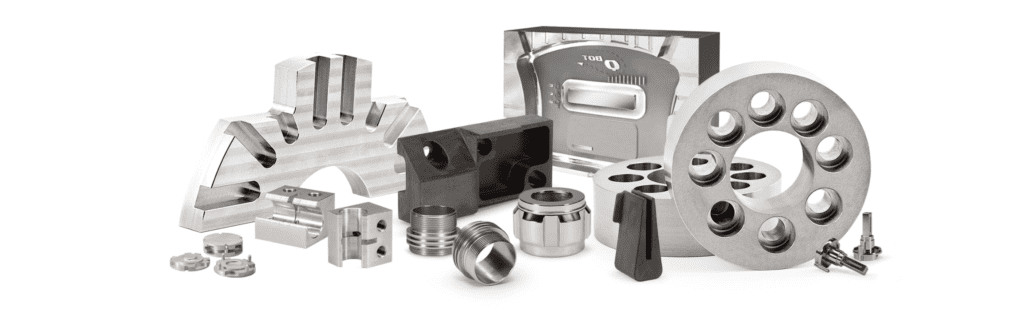

Our dedicated team specializes in supplying parts to equipment manufacturers.

To decrease lead times, our manufacturing facility is open 24 hours a day. We also have several CMMs and vision measuring machines, which allows us to ensure your quality standards.

Our Services include:

Our high speed CNC machines, high-tech tooling, and fast spindle speeds allow us to machine parts at faster speeds and with greater accuracy than ever before.

We produce high-volume, intricate parts from a wide variety of materials. Our experienced machinists and quality control department ensure that we deliver precise parts every time.

Products range from prosthetics and orthotics to medical imaging and implantation devices, and each highly-specialized part needs to function properly.

Whether you need a part designed, reverse-engineered, or prototyped, Advance CNC Machining can advise your team and design your parts for longer wear and better functionality, all at a lower production cost.

Let us maintain your parts and components with our cutting-edge equipment and techniques.

Advance CNC Machining provides CNC prototyping services to American manufacturers, engineers, and funded SBIR awardees.

With our Beamer Laser Marking System, our team can quickly laser mark your part with any image or text that you provide.

Advance CNC Machining uses state-of-the-art inspection equipment and technology to ensure that your parts are made right – the first time.

Core Values

We strongly believe in being incredibly reliable and easy to work with, from our quick response times for new CNC machining quotes to the way we ship your finished parts from our machine shop, and everything in between.

Our commitment to greatness comes from our fundamental core values:

We only do work we’re proud of.

We approach each job cheerfully and gratefully, and put client needs first.

We’re always where we are needed, when we are needed. We’ll help you stay on-budget and on-time, and avoid issues with production.

We strive to be proactive, innovative, and always find a way.

A few months ago, the team at Advance CNC Machining was honored to receive an invitation from Modern Machine Shop to be featured in an article regarding The Costs and Benefits of Horizontal Machining.We had the pleasure of meeting with Pete Zelinksi to share our expertise on the subject. During his time here we discussed our experience with transitioning to mostly horizontal machining centers and the benefits to not only us, but our customers.Some of the benefits discussed in the article include:

- Shorter processing time per part

- Lower Prices

- Three-side machining

- Ability to machine complex parts

- Platform for advanced tooling

- Serving multiple customers simultaneously

- On-machine deburring

- Maintaining a cleaner shop

You can read the full article in the July 2014 issue of Modern Machine Shop or read the full article by clicking here.We are truly honored to have been chosen by Modern Machine Shop to share our expertise on horizontal machining and efficiency improvements. If you are interested in getting a copy of the latest issue stop in and pick one up in our office or get in touch with us and we will mail you a copy.