5 Axis CNC Machining Services

Dramatic Time-Savings and Increased Accuracy

Advance CNC Machining provides high-quality machined parts to manufacturers throughout the country. Our expertise in high-speed, 4-axis, and 5-axis CNC machining makes us one of the most sought-after machining companies in the U.S.

When it comes to your machining needs, wasting time is not an option.

Utilizing Advance CNC’s multi-axis CNC machines allow for shorter lead times and greater accuracy than most other machine shops in the United States. Let us make the investment for you so you can get back to doing what you do best.

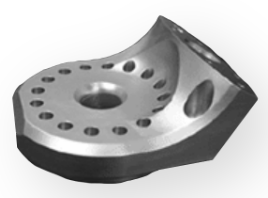

Mounting Head

Average Cycle Time

240 minutes

Our Cycle Time

43 minutes

82% time savings!

12" Elbow

Average Cycle Time

600 minutes

Our Cycle Time

98 minutes

84% time savings!

Rotation Arm

Average Cycle Time

270 minutes

Our Cycle Time

71 minutes

74% time savings!

Advance CNC combines new school technologies with old school values.

High Spindle Speeds

Advance CNC's Makino 4&5-Axis machines achieve faster spindle speeds than most other machines in our industry. This allows for our customers to get parts both cheaper and quicker than other machine shops.

High-Tech Tooling

Advance CNC utilizes high tech tooling designed specifically for handling parts that are difficult to machine. Specialized tooling is just one way Advance can handle parts that other shops cannot.

24/7 Lights Out Automation

Advance CNC utilizes cutting edge automation systems from Makino that allow parts to run light's out, 24/7. We ensure that our customers get what they need, when they need it, every time.

Are you having trouble getting quality parts, on time delivery, or reliable service?

Get a free quote and experience the Advance CNC difference.

Precision 5-Axis Machining Services

High precision and complex machined parts are our specialty. We have invested heavily in our equipment which includes Makino 5 and 4 axis machines. These state-of-the-art machines allow us to provide the speed and precision our customers expect. Thanks to the quality of our equipment and our use of automation, we can cut down on the machining time of complex parts by up to 84%. With up to 5-axes of machining capacity, parts are machined rapidly without sacrificing quality. If you have a need for medium to high-volume machining, Advance CNC Machining is ready to quote your job. Prior to contacting us, you can learn more about our capabilities, equipment, and team by browsing our website. In addition to our robust machining capabilities, we are able to reverse engineer, design or revise parts for manufacturability, and to provide 24/7 industrial part repair throughout Ohio.

Precision Machining Backed by ISO 9001:2015 Certified Quality Assurance

The Advance CNC Machining team also follows an from pre-production through to completion. As an ISO Certified company, we have a tried-and-true method of confirming that any potential errors are spotted before an order is prepared for shipping or pickup. While our machines are efficient, our ISO 9001:2015 QA program confirms to our customers that our quality will match your expectations. When you work with Advance CNC Machining for 5-axis machining services, you can do so knowing that our quality guarantees will always be honored. To learn more about our 4 and 5-axis machining capabilities and quality management system, contact us today.